Education Waxes & Sealants

PURE WAX

SYNTHETIC / CERAMIC

NATURAL WAX

Superior water beading, gloss, and extreme durability

Protection Component:

Ceramic (SiO2) / Carnauba / Polymer

Average Annual Applications:

1 - 2

Defect Removal:

None

Application Method:

Spray and wipe

Machine Application Pad Recommendation:

NA

Recommended Removal Cloth:

Quantity Per Average Vehicle:

1 - 2 ounces

Easy application, ultra durable and hydrophobic

Protection Component:

Ceramic (SiO2) / Carnauba / Polymer

Average Annual Applications:

1

Defect Removal:

None

Machine Application Pad Recommendation:

Quantity Per Average Vehicle:

2 ounces

Deliver incredible color, depth, and clarity

Protection Component:

Carnauba

Average Annual Applications:

3 - 4

Defect Removal:

None

Machine Application Pad Recommendation:

Quantity Per Average Vehicle:

2 ounces

Powerful, long-lasting high gloss protection

Protection Component:

Carnauba / Polymer

Average Annual Applications:

2 - 3

Defect Removal:

None

Machine Application Pad Recommendation:

Quantity Per Average Vehicle:

.5 - 1 ounces

ALL IN ONE

CLEANER WAXES

Flexible paint correction, intense darkness, durable protection

Protection Component:

Montan Wax / Polymer

Average Annual Applications:

3-4

Defect Removal:

Moderate

Machine Application Pad Recommendation:

Recommended Removal Cloth:

Quantity Per Average Vehicle:

2 ounces

Removes light defects and delivers an ultra-durable protection layer

Protection Component:

Ceramic (SiO2) / Carnauba / Polymer

Average Annual Applications:

1-2

Defect Removal:

Light to Moderate

Machine Application Pad Recommendation:

Recommended Removal Cloth:

Quantity Per Average Vehicle:

2 ounces

Removes minor imperfections, enhances gloss and delivers long-lasting protection

Protection Component:

Carnauba / Polymer

Average Annual Applications:

3-4

Defect Removal:

Light

Recommended Removal Cloth:

Quantity Per Average Vehicle:

2 ounces

SPRAY WAXES

Create or extend the shine and protection of your paint

Protection Component:

Polymer

Average Annual Applications:

Following each wash

Defect Removal:

None

Application Method:

Foam and rinse

Machine Application Pad Recommendation:

NA

Quantity Per Average Vehicle:

1 ounce

Superior water beading, gloss, and extreme durability

Protection Component:

Ceramic (SiO2) / Carnauba / Polymer

Average Annual Applications:

1 - 2

Defect Removal:

None

Application Method:

Spray and wipe

Machine Application Pad Recommendation:

NA

Recommended Removal Cloth:

Quantity Per Average Vehicle:

1 - 2 ounces

Adds gloss, shine, and leaves behind wax protection

Protection Component:

Carnauba / Polymer

Average Annual Applications:

5 - 6

Defect Removal:

None

Application Method:

Spray and wipe

Machine Application Pad Recommendation:

NA

Quantity Per Average Vehicle:

1 - 2 ounces

Enhance and prolong the life of your base wax

Protection Component:

Carnauba

Average Annual Applications:

Following each wash

Defect Removal:

None

Application Method:

Spray and wipe

Machine Application Pad Recommendation:

NA

Quantity Per Average Vehicle:

1 - 2 ounces

WHAT DOES DURABILITY MEAN?

Durability claims are always questionable. Anyone who quotes a timeline is relying on foggy conjecture because there are too many variables in the equation to properly answer such a question. It's a "your mileage will vary" proposition because where you park your car (inside a garage or out in the driveway), the climate where you live (bright and sunny versus dark and rainy), how you wash your car (true car wash, dish soap, or the ever-harsh drive-thru tunnel wash), if you're maintaining an existing basecoat, and whether or not your paint was properly prepped before protection was added are all key factors to wax and sealant longevity.

Durability should be looked at as a study of relativity not time... how the formula of one wax stacks up against another... something we call our hierarchy of durability. This is more involved than saying it's a natural carnauba-based wax or a synthetic polymer-based sealant. The ratio of each product's chemistry package produces noticeable differences in durability while also impacting other performance aspects of the product.

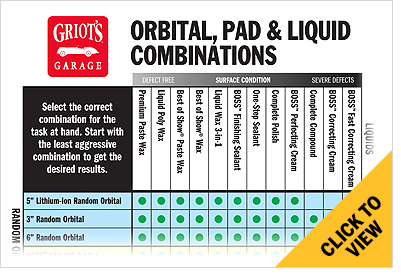

PICK A WINNING COMBINATION

Start by determining the degree of paint correction you need as indicated in the gradated Surface Condition bar at the top of the chart. From there select a product from the Liquids column, match it to your machine, then drop down to the pad section and see which pads will work best.